SERVICES

BUSINESS

For more than six decades

For more than

six decades

Kashima has been a pioneer in

valve plates industry and keeps

contributing to customers with

quality that exceeds expectations.

Kashima has been a pioneer in

valve plates industry and keeps

contributing to customers with

quality that exceeds expectations.

Consistent Commitment

to Quality

Our strength lies in consistent commitment to quality and long-term value that offers to customers. We win the trust by exceeding high standards of quality requirement.

Consistent Commitment to Quality

Our strength lies in consistent commitment to quality and long-term value that offers to customers. We win the trust by exceeding high standards of quality requirement.

Special-Steel Experts

We are experts that deal with special-steel, especially Swedish steel. Our technology that enables thin valves to be durable has been awarded around the globe.

Special-Steel Experts

We are experts that deal with special-steel, especially Swedish steel. Our technology that enables thin valves to be durable has been awarded around the globe.

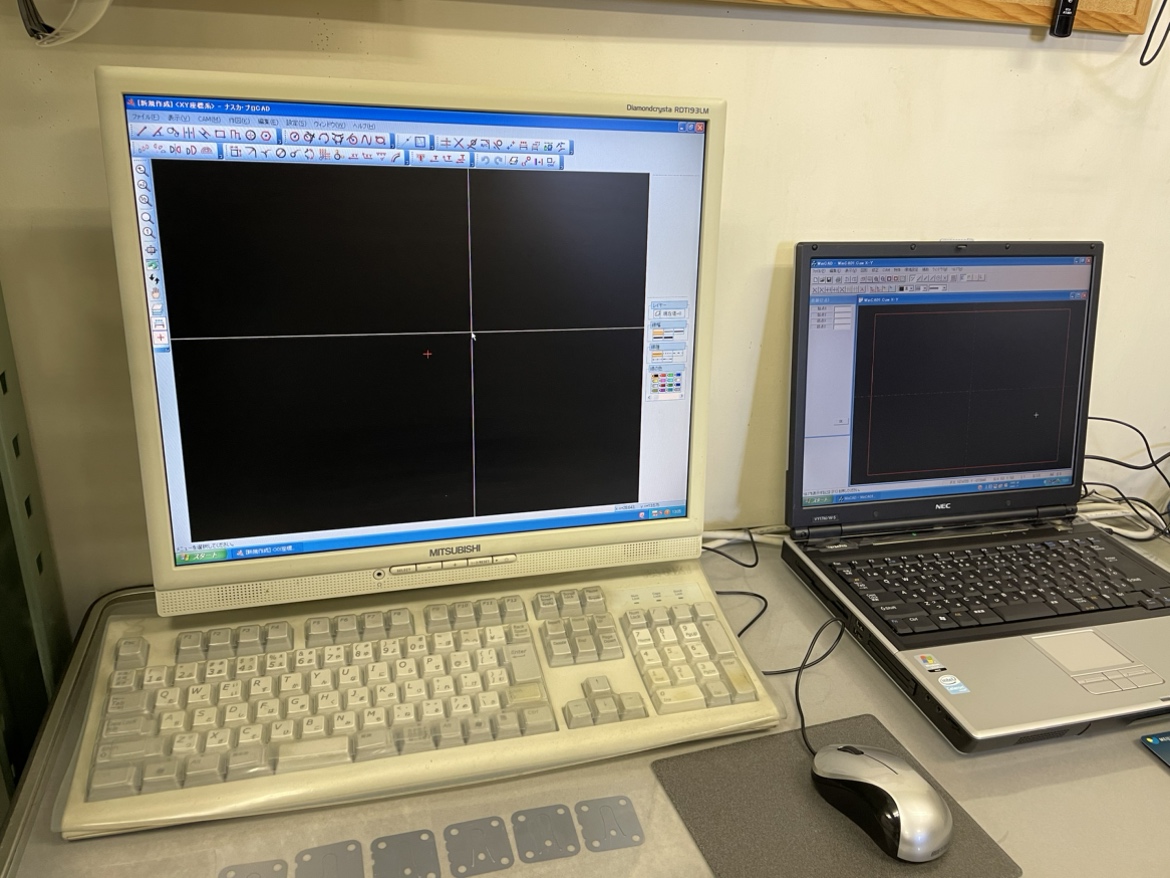

Integrated manufacturing production from mold design and

fabrication to precision stamping and barrel finishing

From mold design and manufacturing to stamping process and barrel finishing, we offer a one-stop service for metal fabrication. We are highly committed to provide excellence of quality.

Integrated manufacturing production from mold design and fabrication to precision stamping and barrel finishing

From mold design and manufacturing to stamping process and barrel finishing, we offer a one-stop service for metal fabrication. We are highly committed to provide excellence of quality.

SERVICES

Pressing

Pressing

To stamp high-hardness metal such as Swedish steel, our dies and press blades are made of cemented carbide (an extremely hard material), and we thoroughly control the hardening temperature of the blades. We also perform maintenance to take care of the dies. Skilled engineers are responsible for fine tuning settings during press work to ensure that we supply products of highest quality. Furthermore, since parts such as valve plates require strength and durability, we use Swedish steel and special hard steels. We are also able to procure other materials to meet customer requirements.

Barreling

Barreling

Barrel finishing is effective for deburring, surface luster finishing, rounding of product edges, and descaling after heat treatment. Advantages of mass production include stable quality (suppression of variation) and lower cost. Rotary barrel machines are common, but with our speciality and over 60 years of experience, we can process any workpieces by adjusting operation conditions. Centrifugal barrel machines are superior to rotary barrels in terms of shorter processing time, with a large number of rotary and centrifugal barrel machines we can process a large volume of products at once. We also have a wide selection of media, our skilled operators are able to determine the appropriate processing conditions and media for each product. We can also handle prototypes and test-products for barrel polishing.

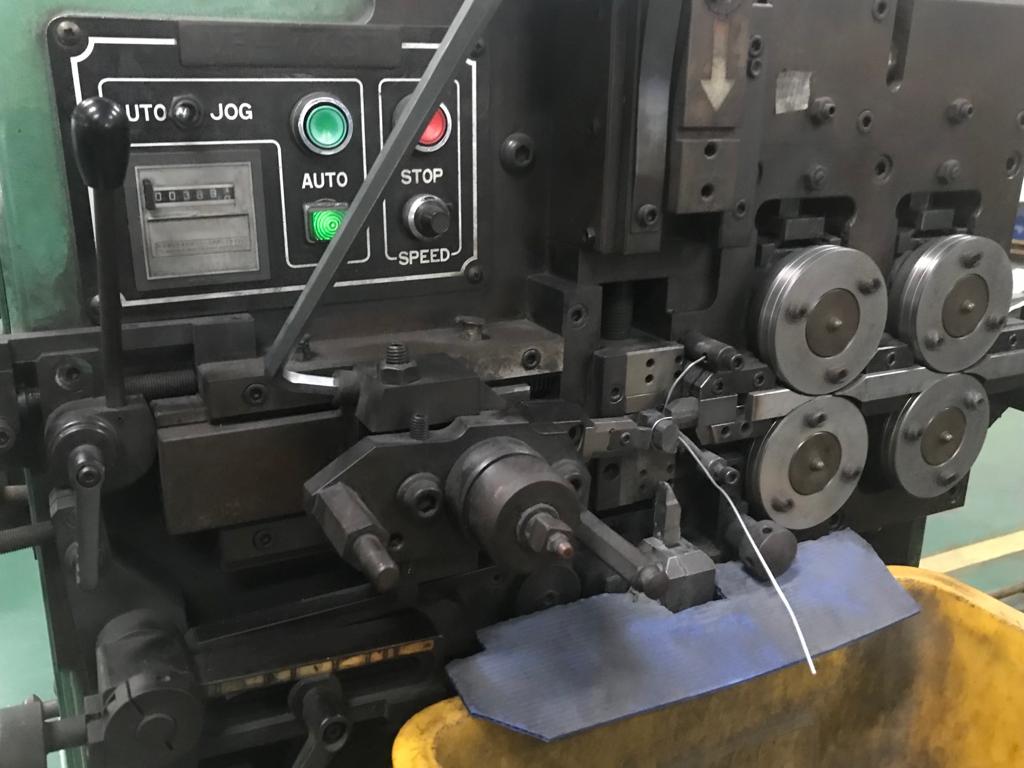

Spring/Coiling

Spring/Coiling

As for coiling products, we specialize in wire diameters from 0.5 mm to 2.0 mm and product outer diameters up to about 55 mm. We mainly deal with piano wire (SWPA/B, SWC) and stainless steel, and deburr the cut surfaces by barrel finishing. We can also arrange materials for square wire (SWPA/B) and surface treatment such as plating and baking as needed in cooperation with subcontractors. The products are mainly used for shock absorbers and brake parts for motorcycles.

Molding

Molding

We develop and manufacture high-quality, high-precision molds that meet all the performance requirements of each product. Our dies are made of hard special metal. We have extensive experience in manufacturing progressive and single-shot molds, and our skilled moldmakers are also available for after-sales maintenance. We also manufacture prototypes and prototype molds in the development and design stages.